Poesis is the Greek work for 'making things'.

Not coincidently, it's also the word for poetry.

A good piece of writing is like a fine piece of cabinetry, an elegant circuit board, or a beautiful engine.

Steve Jobs famously insisted that everything should be beautiful in the IPod, IPad, IPhone -- even if the customer couldn't see it.

A great carpenter feels the same way about the back of a cabinet.

This insight informed my life and the arts I've committed to:

- The art of management, and

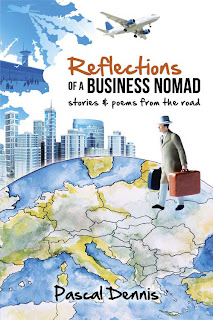

- The art of writing

But do North American high school students appreciate the beauty of making things?

Have they been given proper guidance? Or do they stumble, by default, into barren general arts programs?

(See Oct edition of The Walrus Magazine for a piece on the plight of current graduates.)

I understand, for example, that there are almost a million unfilled skilled trades positions in America.

Good jobs in fields like mechanical, construction and information technology.

A chance to make something beautiful, to learn & practice a great art.

My sense is our kids don't have a full picture of what's possible.

Can I appeal to our friends and colleagues in the Continuous Improvement community to help?

Please spread the message every chance you get.

Making things is COOL.

Pascal